M20 E30 engines are flat tappet engines and require periodic valve adjustments. The loved and distinctive sound of M20 ticking especially when cold, is because of the flat tappet design.

The reasons to adjust your valves includes increased compression because both intake and exhaust valves close fully. Increased fuel economy, and generally improved performance.

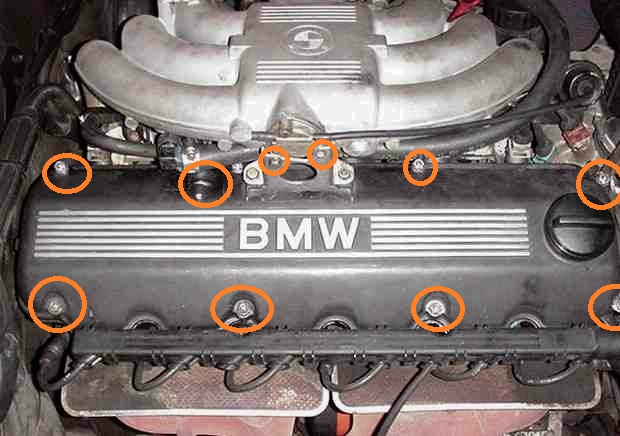

1. Remove the valve cover by undoing the 8 nuts, 1 vent hose and two bolts on the bracket connecting the valve cover to the air intake:

2. Don’t be afraid of this picture, I am only using it to illustrate where the crank bolt is, you do NOT have to take anything off to access it. It is 22mm and should be accessed from below, it will allow you to turn the engine over by hand very easily.

3. Rotate the engine until the lobe of the cam are not touching the rocker. Rotate the engine as per step 2 until the cam lobe for the rocker you are adjusting is pointing down (not engaging the rocker arm at all).

4. Loosen the 10mm nut (do not take off) until you can adjust the adjuster with the allen key, push up to make more clearance, push down to close the clearance. With the feeler gauge while the engine is cold you should be aiming for .010″ = 0.254mm. If you do it while the engine is hot (I do not recommend doing this), you will be aiming for 0.012″ = 0.30mm. The feeler gauge should slide in and out with some drag, if you tighten the 10mm nut and you cant pull the feeler gauge back out then its too tight.

5. Do step 4 and 5 for all intake rockers and exhaust rockers (12 in total). Recheck that all 10mm nuts are tight when you are done, and double check that all clearances are correct.

6. Change the rocker shaft plugs. They are rubber and cheap from the dealer (11 33 1 264 519). It is not required to change these, but over time they begin to leak oil. To get the old ones out, I used a longer wooden screw to screw into the rubber plugs and then pulled up and out with pliers. The new ones just push in by hand.

7. Put the new valve cover gasket on, and put a bit of RTV where the shaft plugs are, to help that transition between aluminium and rubber seal better.

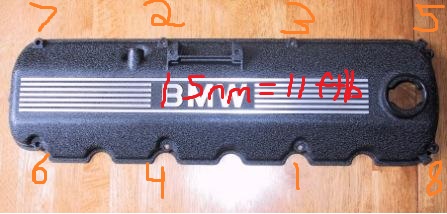

8. Put the valve cover back on and tighten the Bolts in this sequence to 15nm (11ftlb), dont forget to put the spark plug wire bracket on the stubs before tightening 4 and 1:

9. Reattach vent hose.

10. Done!

Thanks for the useful info.

What part would be worn out first if tappets are still noisy after adjustment? Is it the valve eccentric or lobes of cam?

You will not eliminate the sound after an adjustment, the fact that the engines are tappet engines means that you will always have a certain level of ticking.

Hi – I just suffered an “interference situation”; not a belt breakage – but an idler shaft shearing…same effect – valve/piston collision. My question: Beyond the usual bent valves (all intake ) and broken rockers (all six intakes ), I have one badly nicked piston top. I’d say that the depth is as much as a 1/16″ in a few locations. If I grind/polish out the high spots, is there much of a chance of “burning through” the injured piston? Thanks for your opinions. Paul

You can do both valves at once. When turning the engine, you want the lobes to be in a inverted V over the valves on the cylinder you are adjusting. If you give the rocker arms a wiggle on both valves, you will feel a slight bit of play and hear a faint tick as you move them. If you get this on both rocker arms, that means the valves aren’t being engaged by the cam, and both the intake and exhaust valves can be checked.

If you start from TDC on cylinder 1, continue in the firing sequence. Since I have an open diff, I put the car in 5th and jack one side of the car, and turn the tire to turn the engine. I’ve found that it’s roughly 1/4 to third of a turn to follow the firing order.

You can actually adjust more then 2 at a time, but I wouldn’t recommend that, I would make sure to be methodical and work on 1 valve adjustment at a time; making sure the lobe is pointing completely away from the valve you are working on.

I would suggest relying heavily on visually confirming the lobe is no where near touching rather then by feel of play in the rocker arm.

Rotating the engine is much easier via the crank bolt using a 22mm wrench, however your method does work also.