When you hear or read someone say not to put anti-seize or another lubricant on your threads just remember; torque is just the means to getting appropriate tension. The problem is, tension goes both ways, and dry torque specs assume clean new threads.

As this video illustrates, a less than new bolt yields only 28% of needed tension per the same torque versus a new bolt/nut.

After applying lubrication to the corroded threads, he was able to get it back to 90% of the initial tension per same torque.

Similarly, lubricants will yield you anywhere from 25-35% extra tension per incremental torque.

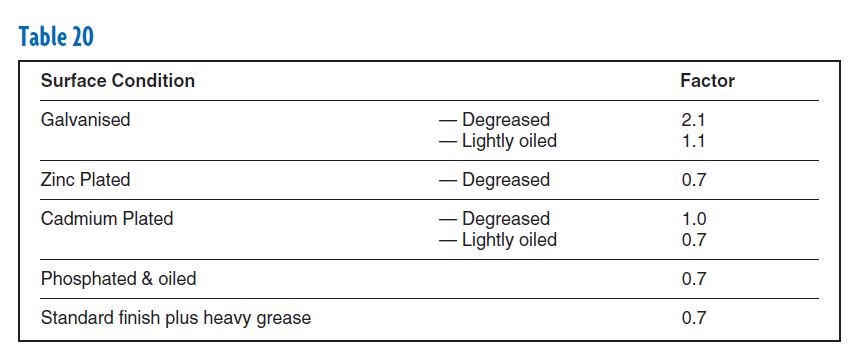

Most bolt makers give torque specs for dry, zinc plated, and lubricated; in small fine print assuming friction by saying something to the effect of: “Torque values calculated from formula T=KDF where; K=0.15 for “lubricated” condition, K=0.17 for zinc plated and dry condition (or as-received for the 12.9), K=0.20 for plain and dry

condition ”

So the question really isn’t whether to use a lubricant or not, its more a question of what your working on and how much effort you are willing to put in cleaning the threaded surfaces.

In any case, anyone using a torque wrench with a 0.7 factor (torque spec * 0.7) on a new bolt to a dry torque rating wont over yield (deform) the bolt/stud even while using a heavy lubricant.

https://www.rtsauto.com/wp-content/uploads/2018/06/ajax-handbook.pdf

The probability of someone over deforming the threads while not using a torque wrench certainly goes up with lubrication, because the window for over tightening is smaller.

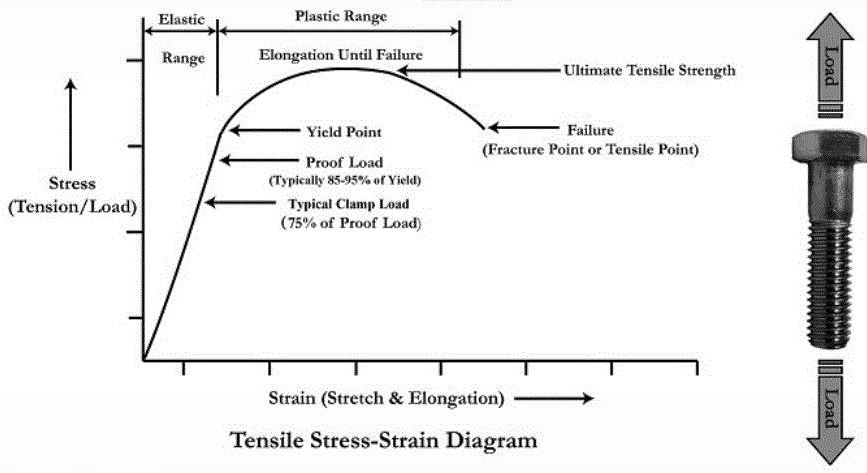

However, unless the bolt enters the plastic range, it wont elongate, even if loosened and tightening numerous times.

On a macro level, lubrication definitely leads to more elongated studs, margin for error becomes smaller, and therefore more errors happen, particularly in high pace environments where impact guns and tightening by feel is common. But remember, that’s user error.

At the end of the day, if you work on your own car, its a good idea to use some lubrication to avoid corrosion.

Recent Comments