If your into cars and cars as old or older then the E30 then inevitably you will need to weld something weather its for performance reasons, repair reasons, or rust reasons.

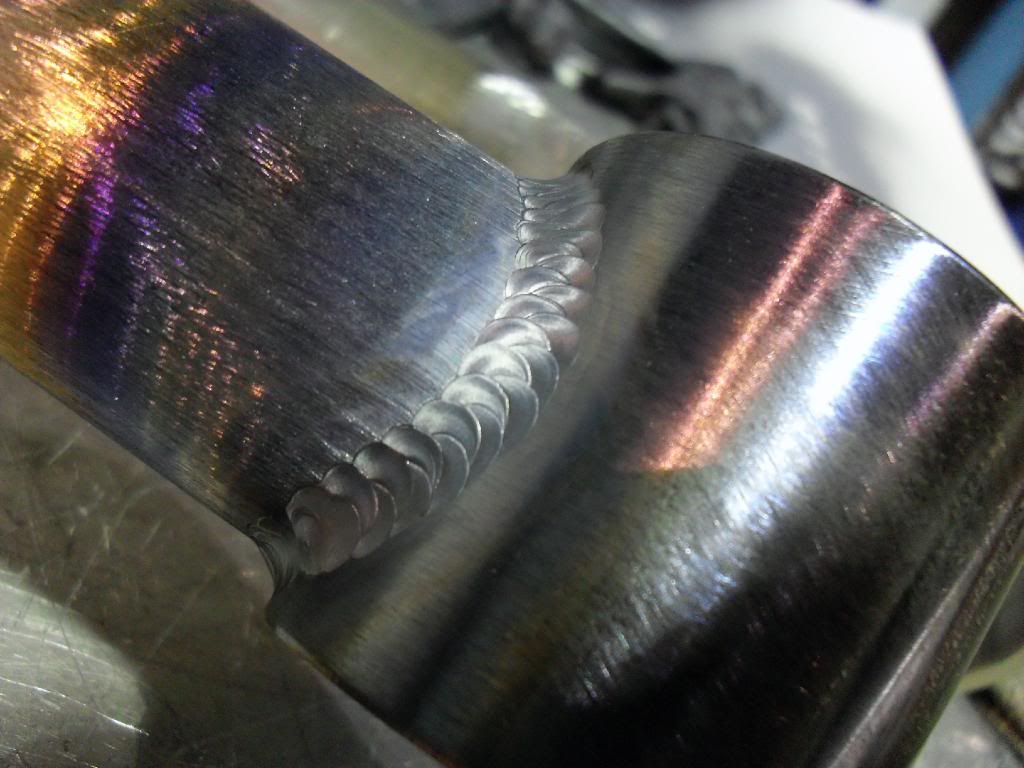

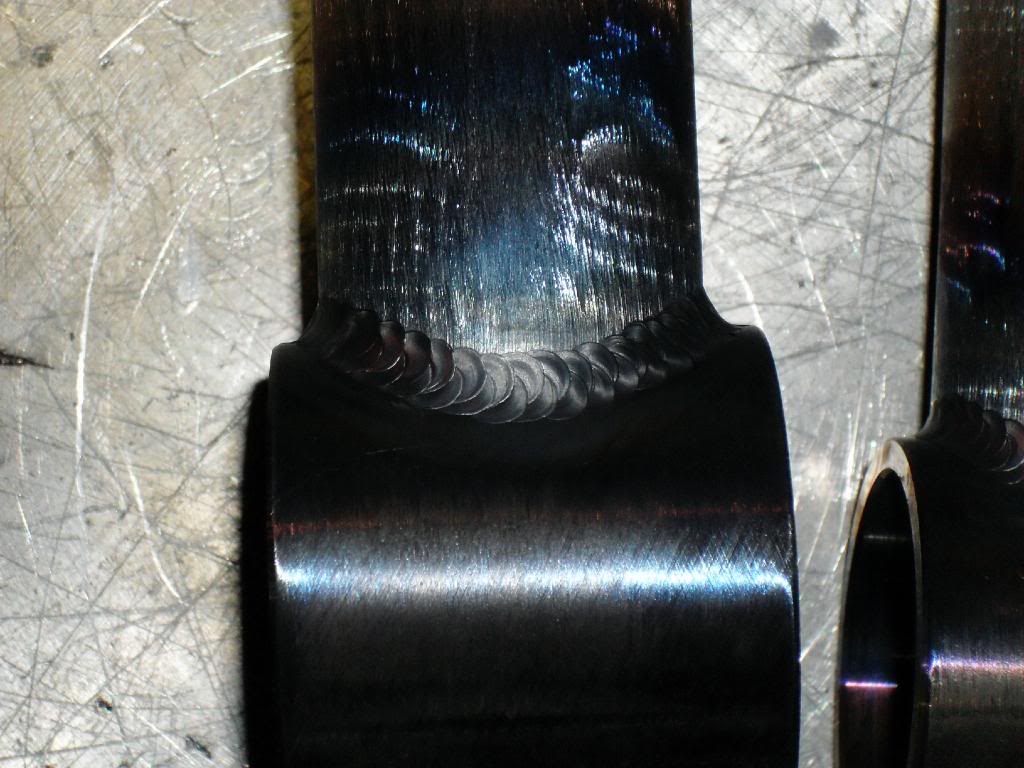

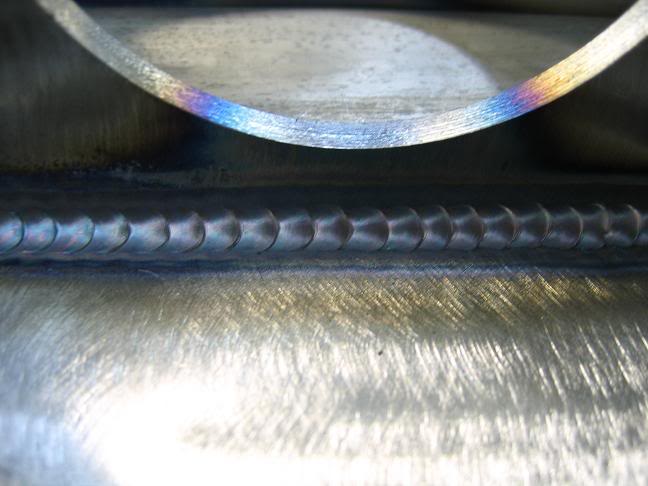

A few perfect (i would call them works of art) pictures of welds sparked my desire to cover this on rtsauto:

There are 4 main types of welding (tig, mig, arc, and oxy) I will cover the first three as the forth isnt very effective, should be used more for cutting:

Tig welding is what all the above photos are, they are beautiful, clean, strong, and can weld virtually any metal. Problem is its not point and shoot as you must feed sticks with your other hand. It also isnt as fast as mig or arc (see below). For precision work pick/learn this form of welding.

Mig welding is point and shoot, doesnt look as crisp (with skill) as tig but can still produce a very nice and respectable looking weld. Problem is that you can only weld steel and aluminum (with special gas: argon). There are two types of Mig welders

Flux core, there is flux within the feeding wire which produces a protective shield while welding to help form the weld by protecting it from oxidation, but it creates some splatter and thus isnt as clean. Flux core can usually per same voltage/current weld thicker then with gas. Flux core works well outdoors because wind doesn’t effect it much unlike with gas. It is also very convenient because you dont need a tank/regulator/etc that is needed with a gas. You can not weld aluminum with flux cored, it is limited to steel.

Mig gas welders use gas from an external scuba looking tank to create a protective shield for the weld while welding. Depending on the gas an mixture it can weld not only steel but aluminum also. It creates a clean splatter free weld, but the working area must be shielded from wind and drafts so the gas isnt blow away while welding which could compromise the weld.

Arc welders are usually the cheapest of all welders, but be careful because arc welders is the least clean/precise welding technique. Basically there you take a rod and stab at the place you want to weld, lots of splatter, and not very precise. This technique is usually used to weld things outside because it is not effected by wind. It is used outdoors and indoors to weld very large pieces of metal together, because big/lengthy welds are required in these environments.

Do yourself a favor and get an auto darkening welding mask, the lense is see threw when not welding and then instantly darkens when you start welding, not only are these completely hands free but they will also teach you to weld better because you can see where your welding, and pointing at all times.

Recent Comments