One of the most frustrating parts of doing suspension work, especially for someone who doesn’t have a ton of experience is loosening or tightening the nuts on balljoints; because they spin.

They are designed to spin, and sometimes need to be persuaded to not rotate so the ball joint nut can be tightened or loosened.

If removing, always spray the threads with penetrating fluid such as wd-40, PB Blaster, or anti seize, or if none of those are available, some basic oil. The primary purpose is not to get the fluid into the threads of the nut. The purpose is to allow for a lubricant towards the top side of the balljoint, where you will face the most amount of corrosion while removing the nut.

Most balljoints have either an allen, torx or external hex attachment to hold the balljoint from spinning. But from experience, normally the hex strips out, is inaccessible because of an axle or for external hex attachments, the nut gets stuck at the top preventing you from being able to finish taking the nut off.

The best thing to do is to place a jack under the balljoint you are working on, and to lift up on the joint to put pressure between the balljoint housing and the balljoint and knuckle. This will work for both tightening and loosening.

For loosening only where the balljoint will be replaced:

If the balljoint continues to spin (normally only a problem when loosening and corrosion is a big factor).

Take a pair of locking pliers prefereably a set with an adjustment screw that allows for additional socket tightening:

Place these locking pliers on the shaft of the balljoint. For added pressure, place the jack under the balljoint again and compress the locked pliers between the knuckle and the balljoint.

Balljoints almost always have a widening of the shaft going into the boot, or a metal lip inside.

The locked pliers will bite deeper into the shaft as you use the jack because it will slide down the shaft where the shaft gets wider or has a lip.

If its still not coming off:

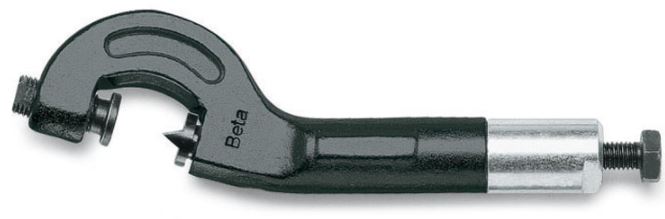

Depending on what car you are working on, and what balljoint, you may have sufficent access for a nut splitter.

Which is also available in this style:

As you tighten the nut splitter, it will split and break the nut off the shaft.

Another option is to heat to expand and contract the nut. Oxy-acetylene being the best option, however for the home warrior, MAPP gas is more easily available and safer. It can be purchased from your local home hardware store. Dont think of using propane, it doesn’t burn hot enough.

If all else fails, use a dremel with a cut off wheel, a metal hand saw, or an angle grinder with a cut off wheel to cut the shaft of the balljoint off.

Recent Comments